|

|

INTRODUCTION:

STAR TRACE Roll Magnetic Separator is a roll type dry magnetic separator with fixed magnet having high field intense and gradient. The magnets used in the Roll Magnetic Separators and made of alloys of rare earth elements are more powerful as compared to other magnets. They generate high attraction forces on the magnetic roll due to their properties and special magnetic series. The obtained high magnetic attraction forces have low magnetic sensitivity and therefore they make it possible to separate very fine low magnetic minerals with a high recovery.

The most distinguishing property of Roll Magnetic Separator is the used magnets that are an alloy of rare earth elements produced domestically and more powerful. Magnetic Systems has a number of standard sizes in which the high gradient separator is produced, and all of these sizes only require a low installation height. It is also possible to make a system in accordance with customer specifications. Depending on the requirements made and the application, a choice can be made for a single stage system or for multiple magnet rolls under one another. This results in an even higher degree of iron separation.

Working Principle:

Roll Magnetic Separators consist of two rolls, one of which is magnetics. There is a belt between them to carry the ore into the magnetic field. The movement of the belt is controlled by a motor fixed to one of the rolls. The rotational speed of rolls can be adjusted according to the material properties.

The material to be processed is conveyed to the belt by vibrating feeder at a required rate. Feeding rate can be controlled by adjusting the vibration on feeder. A separator blade has been set in order to be able to collect separated products in different places and to adjust the product properties in a desired manner.

Technical Features

- Standard 2.5, 2, 1.5, 1, 0.75, 0.5 and 0.25 meter wide magnetic roll. Also available in a laboratory scale model with readily interchangeable rolls of 100 mm length.

- Supplied with a vibrating feeder to suit the roll width.

- Simple conveyor belt tensioning and tracking system accessible at the sides of the machine.

- Fixed or-variable speed roll drive options. Fractional HP motor having voltage and frequency to suit user.

Operating variables are:

- Field strength (measured indirectly and controlled by amp adjustment of the electromagnet) typically up to 15,000 gauss.

- Pole gap (closer the gap higher the field strength), typically 2mm.

- Roll speed ( normally fixed and only adjusted by pulley and belt changes).

- Splitter position (determined by visual observation of the fan).

- Feed temperature will affect magnetic susceptibility.

- Feed rate typically 2.5tph.

Roll Construction:

The magnetic rolls incorporated in our machines have been specially designed and developed to generate exceptionally high magnetic field and gradient. The rolls which are built using rare earth Nd-Fe-B are manufactured to very low dimensional tolerances. The magnetic rolls incorporated in our machines have been specially designed and developed to generate exceptionally high magnetic field and gradient. The rolls which are built using rare earth Nd-Fe-B is manufactured to very low dimensional tolerances.

Applications

|

|

Features

- Compact construction.

- Single or multi stage separation.

- Fully enclosure with dust extraction port.

- Designed for easy maintenance.

- Automatic belt tensioning and tracking.

- Tool free belt change.

Uses

Induced Roll Separators are primarily used for separating or concentrating minerals or materials of low magnetic susceptibility. Uses include extraction of iron or chromium bearing minerals from silica sand, the concentration minerals such as wolframite, the removal of paramagnetic minerals such as Iron Titanium Oxide (Ilmenite, FeTiO3), Iron Carbonate (siderite, FeCO3), etc., from valuable non-magnetic minerals, and purification of dry granular chemical compounds and abrasives.These self-cleaning magnetic separator selectively removes magnetic components out of a conveyed material and discharges them as distinct and clean material. Field intensity is adjustable for selective recovery. Very high gauss of 20,000 is achieved by the magnetic separator.

The throughput and degree of separation depends upon the following factors:

- The susceptibility of the magnetic fraction - throughput is reduced for materials of lower magnetic susceptibility.

- The particle size - for most materials the maximum size which can be satisfactorily treated is 3mm. For the treatment of dry materials up to 50 mm in size, electromagnetic multi-channel Pulley or Drum Separators are available (details available upon request). The presence of fine particles (particularly those less than 30 microns) reduces throughput.

- The bulk density - higher values increases throughput.

- The flow characteristics - these are determined by particle shape, surface condition and moisture content. Better flow characteristics increase throughput.

- The proportion of magnetics - a high percentage of magnetics may reduce throughput.

Specification:

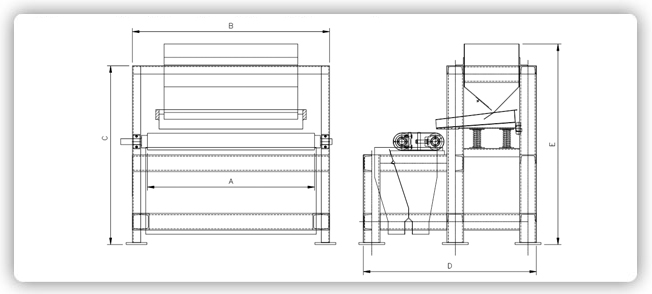

Single Roll Separator

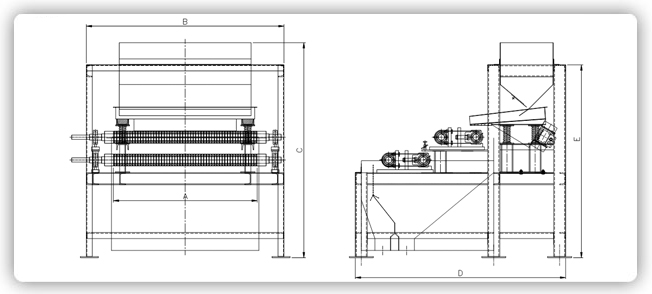

Double Roll Separator

Specification details for Roll Separators

| Specifiations for Single Roll Separator | ||||||

| Model No. | Belt Width | A | B | C | D | E |

| STR-RS-250 | 250 | 250 | 450 | 1070 | 1035 | 1200 |

| STR-RS-500 | 500 | 500 | 700 | 1070 | 1035 | 1200 |

| STR-RS-1000 | 1000 | 1000 | 1200 | 1070 | 1035 | 1200 |

| STR-RS-1500 | 1500 | 1500 | 1700 | 1070 | 1035 | 1200 |

| Specifiations for Double Roll Separator | ||||||

| Model No. | Belt Width | A | B | C | D | E |

| STR-DRS-250 | 250 | 250 | 500 | 1795 | 1755 | 1610 |

| STR-DRS-500 | 500 | 500 | 750 | 1795 | 1755 | 1610 |

| STR-DRS-1000 | 1000 | 1000 | 1250 | 1795 | 1755 | 1610 |

| STR-DRS-1500 | 1500 | 1500 | 1750 | 1795 | 1755 | 1610 |